A Beginner's Guide To Custom Antibody Production

Mar 9th 2022

A Beginner's Guide To Custom Antibody Production

The employment of custom antibodies as potent agents in biological and diagnostics has transformed and restructured the world of modern medicine, environmental and “in situ” monitoring, and laboratory-based science. Polyclonal antibodies, Monoclonal antibodies (mAbs), antibody fragments, and recombinant antibodies all utilize various purification techniques.

In addition, the ongoing potential of antibody production through recombinant procedures has enhanced the requirement of purification extensively, which goes up to 100-kilogram batches. Hence, the process requires indigenous purification strategies and methods. To obtain the ongoing industry standards for purification, investigators commonly utilize affinity chromatographic affinity ligands. However, in the modern age, consider the movement where protein can be used as a bioaffinity ligand. This is because of several restricting elements like Protein A leakages from the column, low reusability of resin, high cost, and assumed antibody aggregation during the low pH desorption.

If you weren’t aware, a researcher could alternatively achieve antibody purification through genetically fused purification tags, the most typical of which is a poly-His or His6 utilized in IMAC. In this process, the utilization of ion-exchange chromatography through the platform of multicolumn countercurrent solvent (MCSGP) systems has been quoted by scholars as an ideal replacement to protein A-based chromatography. This arrangement can recycle partially purified fractions, enhancing the whole protein yield. Furthermore, it can simulate models and experimental setups while achieving commercial yield levels with the utmost purity.

Antibodies come in various shapes and sizes.

Gerald Edelman and Rodney Porter initially elucidated the feature Y-shaped antibody structure. However, in late 1972, they were awarded the Nobel Prize for Physiology and Medicine for their discoveries. The Y-shaped yields they found were later acknowledged as (IgG). It is composed of four polypeptide chains – two light chains (25 kDa) and two heavy chains (50 kDa). Besides, these chains are associated with disulfide bridges and noncovalent bonds.

The primary operational custom antibody elements are antigen-binding and the Fc platforms. Moving on, the region is further controlled of variable light and heavy parts with the Fc section associated with constant H1, H2, and H3 areas. Having said that, modern medicine today occurs in all sizes and shapes. Moreover, they were discovered in mammals and different formats all over the animal kingdom.

Regardless of the naturally-transpiring formats, the combinatorial deoxyribonucleic acid technology has also facilitated the growth of recombinant antibodies like disulfide-stabilized Fv antibody fragment, fragment variable (Fv), fragment antigen-binding (Fab), single-chain fragment variable (scFv), divalent antibody formats like mini-body, diabody, and multivalent sections like triomabs, tetra bodies, F(ab)3, and triabodies.

What are the conventional methods?

When it comes to a specified form of antibody purification method, researchers perform it through affinity chromatography or tag-based procedures under the same light. Not only does it obtain a significant purity but also selectivity. However, the entire process can be expensive if you intend to perform such an activity on a vast scale. To reduce cost, one can employ physicochemical separation techniques before affinity chromatography to eliminate many contaminants and avoid fouling. A brief introduction of both processes is mentioned in the rundown.

Affinity chromatography

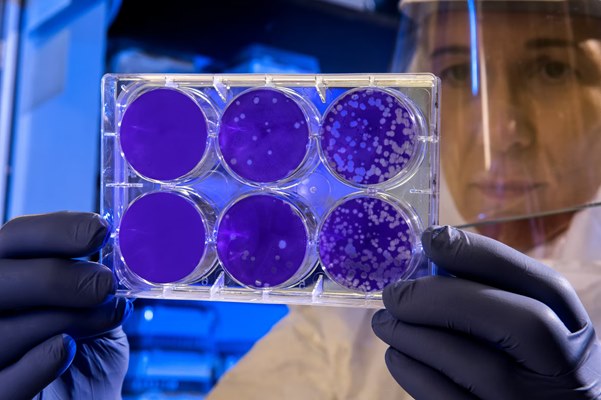

Monoclonal antibodies are commonly utilized as potent agents in cancer reception, inflammatory issues, and autoimmune conditions. Speaking of which, such entities need the highest purification acceptance before getting administered for patient procedure. Moreover, monoclonal antibodies move towards batch purification from mammalian cells like CHO cells. Researchers then consider eliminating impurities like endogenous infections, host cell proteins (HCPs), DNA, aggregates, and endotoxins that are primarily integral as they can potentially trigger a patient’s immune system network.

In this case, investigators usually perform the removal procedure through several steps and techniques, out of which the most prevalent is a combinatorial approach. For instance, using a protein-A affinity agent is associated with anion-replacement chromatography.

In bioscience, studying affinity tags is integral for a researcher. This is because of their importance in the purification process. While moving into the procedure, you can express and encode the tags as fusion partners with a specific protein. In addition, they can survive as single amino acids, light polypeptide chains, or complete proteins. Despite the increasing facilitating identification, specified affinity tags can profoundly increase protein stability and accommodate native folding.

N-terminal GST

The N-terminal GST is typically utilized as affinity tags for recombinant antibody purification. Besides, GST is one of the monomeric proteins initially discovered in Schistosoma japonicum. When it comes to the elution conditions, they are mild since alleviated glutathione can be utilized amid the competitive elution program. Having said that, the purification process of significantly concentrated GST-merged proteins can lead to aggregated proteins, which could be agreeable concerning the chosen application. In addition to specific applications, high-molecular-weight fusions can lead to fully or partially insoluble aggregates.

Physicochemical Fractionation: Membrane Filtration and Precipitation

While recovering the initial antibodies, it is essential to alleviate turbidity and facilitate impurity removal. Turbidity, emerging because of the availability of cell debris during the tissue preparation or cell lysates, should be taken out before adding the mixture to chromatographic columns as it may clog the bed.

Moreover, the physical procedures of central antibody recovery like filtration and centrifugation are routinely performed in the initial period of the entire purification method. When researchers perform the purification procedure through centrifugation, particle separation is typically based on their centrifugal force.

Centrifugation expedites antibody-containing supernatant separation from the cellular debris and cells. But, elements like residence time, g-force, and discharge frequency could influence clarification efficacy and vary considerably while moving from small-scale to large-scale centrifugation.

Membrane filtration, like ultrafiltration, microfiltration, and depth filtration, allows slight molecule separation by size, whereas charged ultrafiltration can detach proteins through the factors like charges and dimensions. For instance, investigators use cellulose-based ultrafiltration membranes to separate various therapeutic monoclonal antibodies from CHO cells. However, when it concerns the microfiltration membrane chromatography, it is ideal to know that the process can remove biological entities like viruses, DNA, and protein contaminants from fluids utilizing microporous membrane filters, examples of which comprise polyesters and polypropylenes.

What’s depth filtration?

Depth filtration is the primary workhorse of cell illumination. An investigator can utilize depth filtration before complex mediums get applied to chromatography columns. Depth filtration can also be subjected to high propensities for the medium to plug or clog polishing membrane filters. To make it simpler, depth filters are usually composed of filter aids and cellulose fibers associated with a positively-charged polymer resin. While amid the depth filtration procedure, investigators tend to retain the contaminant particles throughout filters instead of staying at the table’s top.

If you take the particle retention theory, you can toggle through the combination of size adsorption and exclusion through ionic, hydrophobic, and other interactions. In addition, chemical processes and techniques for reducing turbidity comprise precipitation, flocculation, and crystallization.

Crystallization is a highly beneficial tool. It can contribute to the concentration, stabilization, and purification of the whole antibody product without the requirement for affinity tag removal and affinity tags. Transformations in such methodologies can be discussed in considerable detail in the “non-chromatographic techniques” section.

Antibody production

When it comes to the term antibody production, it has specific and general denotations. In a general sense, it refers to the whole process of developing a particular antibody utilized in several forms of experiments. This may include immunization steps, immunogen preparation, collection, hybridoma creation, purification, screening, isotyping, and labeling for uninterrupted use in some methods.

When one talks about its restricted nature, the production of antibodies also comprises antigen sample preparation and secure injection into farm or lab animals. That’s because the animals tend to promote high expression percentages of antigen-dominant antibodies amid serums, which further hinders an animal.

However, in the case of producing polyclonal antibody steps, researchers can recover them directly from bleeds. On the other hand, antibodies are made by fusing antibody-secreting cells to develop the monoclonal hybridoma cell lines that can express particular antibodies. Some bioscience departments also propose a specific protein expression service, custom protein expression, and various forms of antibody sequencing services.

Triumphant antibody development relies on straightforward implementation and planning for many essential considerations and techniques:

- Purify target antigens

- Select a suitable immunogenic carrier protein

- Consolidate the carrier and antigen protein to produce immunogens

- Immunize target species utilizing suitable adjuvant and schedule formula

- Screen serum or hybridoma for antibody titers and isotypes

Antibody purification

The steps under antibody purification comprise antibody isolation from polyclonal antibodies, culture supernatant, and ascites fluid. In addition, purification techniques range from crude to concrete models given in the rundown:

- Crude - subset precipitation of total serum proteins including immunoglobulins

- General - specific antibody affinity purification classes without antigen specificities

- Thorough - affinity purification of selected antibodies that interact with specific antigen molecules

Antibody characterization

This process comprises three types of activities usually performed at multiple stages throughout the antibody production service and purification procedure:

- Screening - determining antibody samples with antigen-binding specificity

- Titering - calculating antibody functional assay titer and concentration

- Isotyping - checking monoclonal antibody classes and subclass identities

Moving on, the screening step is one of the most important ones in the development of identifying which hybridoma clones and animals are creating the utmost levels of antigen-specific antibodies. Such a step comes under antibody validation, which is typically accomplished utilizing ELISA methodologies. Moreover, researchers estimate the antibody concentration by using either standard protein assays or species-related assays like with specialized microagglutination assay platforms. Speaking of which, antibody titer is correlated to concentration. However, it refers to the efficient potency of specified antibody samples.

Studies have stated that measuring titers simply means determining or acknowledging the functional dilution of antibody samples essential for detecting a specific assay, like ELISA. Besides, isotyping comprises checking the subclass and class of monoclonal antibodies. It is vital to know that this is one of the integral steps in producing antibodies, be it polyclonal or monoclonal. This also intersects with the idea of selecting a suitable modification and purification process for a specific molecule. In the end, isotyping is relatively easier to determine with synthetic and commercial antibody kits.

Antibody fragmentation

Investigators have earlier modified antibodies for specific uses through various methodologies consisting of fragmentation into meager antigen units. Moreover, most of the antibodies are utilized in whole-molecule forms. However, the staging of a few experiments and techniques can be enhanced by employing antigens whose redundant portions have been eliminated.

Antibody fragmentation also refers to processes to cleave apart the entire antibody molecule and remove portions not necessary for binding. F(ab)'2 and Fab have selected antibody fragments most frequently developed and used by investigators.

Antibody immobilization and labeling

If you’re thinking about how antibodies are produced and purified for studies as antigen probes, their use in any technique (western blotting, ELISA, immunohistochemistry, cellular imaging) relies on adorning a mechanism to detect antibodies. Methods that can operate antibodies for immunoprecipitation or various types of affinity purification depend on specific mechanisms of antibody production for binding and immobilizing to beaded agarose resin. Processes for achieving such a result involve similar considerations and chemical techniques as antibody labeling.

Features and elements of monoclonal antibodies

Studies have shown that you can characterize monoclonal antibodies thoroughly prior to employment. Such an element must include the biochemical and biological properties of the antibodies. In response to the process, a researcher can assess the reactions and specificity of the antibodies.

Biochemical characterization

When it concerns biochemical properties, one should describe them in detail. At a minimum, they should be classified by an investigator while proceeding in the experiments. Moreover, you should describe the immunological nature of the antibodies in detail where the elements should comprise antigenic specificity, antibody epitope, the ability for activation and complement, binding capacity, antibody-dependent cytotoxicity, cytotoxic properties, antigens relevance, and the potential to accommodate immunocompetent cells.

Single harvest production

One must know that the maximum permissible generation amount for production is defined and based on the cell line stability and production levels. On the other hand, where are antibodies produced? Here, the multiple harvest production includes the recurring cultivation that a scholar can specify to stabilize the system beyond any limit.

The Bottom Line

Since biochemicals and biosciences have significantly transformed in the past few decades, investigators and researchers find more mediums to support their experiments. However, concerning custom antibody production, several companies are offering protein expression and purification services, peptide synthesis, gene synthesis, along protein production services while determining even the minute factors involved.