Recombinant Protein Expression Process

Dec 1st 2022

The production of recombinant proteins is essential but only sometimes straightforward. Since many things can affect how proteins are made and purified, the optimization process is usually labor-intensive and takes a long time.

Several biopharmaceutical protein expression specialists provide specially made bacterial expression services with modern systems to address some uncertainties and difficulties. From codon enhancement to gene synthesis to marginal testing and scale-up, in addition toprotein purification and characterization, users can now select a solution that best meets their needs.

In addition, biopharmaceuticals have developed a large-scale manufacturing protein refolding technology for restoring biologically functional proteins from inclusion bodies. The high throughput Escherichia coli (E. coli) expression platform provides a cost-effective alternative for small-scale expression, thereby accelerating target screening projects.

However, getting a specific protein form within a particular cell line in reasonable quantity and quality is challenging. Pharmaceuticals can do this through genetic modification, optimization of the expression vector, changing the cell line, and optimization of the process.

Read on for a detailed examination of the Recombinant Protein Expression Process and its advances and challenges. Let’s start by delving deeper into what is meant by Protein Expression.

What is Protein Expression?

The initial step in the production of proteins is protein expression, which is accomplished by altering an organism’s gene expression to cause it to produce high levels of a recombinant gene.

Proteins are expressed by a process called Transcription, in which an RNA copy of the DNA code is made and translated information carried by nucleic acids into the amino-acid sequences that make up proteins. A second method for processing protein expression is known as Translation. It involves both the expression of genes and the synthesis of proteins.

The two main steps in converting genes into proteins are Transcription and Translation, respectively. Methods such as strain selection, fusion systems, codon optimization, co-expression, mutagenesis, and isotope labeling are frequently employed to produce sufficient quantities of the protein of interest.

The Process of Protein Expression

Proteins in eukaryotes are synthesized through a different mechanism than those in prokaryotes.

In eukaryotes, it occurs in two distinct locations and periods:

Transcription occurs in the nucleus, and while Translation occurs in the cytoplasm. Polypeptides undergo post-translational modifications to finalize their structure, specify their subcellular localization, and control their activity.

However, unlike eukaryotes, Transcription and Translation are not two separate steps in prokaryotes. The mRNA translation begins even before ultimately synthesizing the mRNA transcript, and a gene’s Transcription and Translation can co-occur, a process known as coupled Transcription and Translation.

Background on Recombinant Protein Production

Researchers in biomedical science, biopharmaceutical research, toxicology, and biology have been using monoclonal antibodies (mAbs) since the 1970s to make discoveries in their fields. Cancer, autoimmune diseases, and bacterial infections are just some diseases that can be treated well with monoclonal antibodies.

Producing a monoclonal antibody has traditionally taken between six and eight months. But researchers have come up with other ways to make antibodies because the number of people who need them is growing faster. An example is the use of commercially available systems and synthetic genes to produce antibodies in a recombinant way.

Synthetic genes help create recombinant antibodies (rAbs), monoclonal antibodies produced in vitro. First, the heavy and light chains of the antibody are taken apart and put into an expression DNA vector. After that, the resulting plasmids are transfected into a host expression system to be expressed.

The recombinant antibodies from this process can be used in many ways, like monoclonal antibodies. Antibody production, once taking between two and three months, can now be done in as little as one or two months with the help of this technology.

Recombinant antibodies can be produced using a variety of prokaryotic and eukaryotic systems. Even though both systems have pros and cons, this article will focus on the mammalian expression system.

If you want to learn about a protein’s function in a setting as close to the body as possible, mammalian expression is the way to go. The protein can undergo extensive post-translational modifications and maintain its full functional potential using this system. Mammalian expression is often used to make native antibodies, therapeutic antibodies, and antibodies used in cell-based assays.

Since antibodies can be different in size, shape, how they fold, and other ways, there are various ways to improve their expression. The best way to describe how recombinant antibodies are made is by their yield, quality, and effectiveness. The expression of recombinant antibodies can be hindered by protein insolubility, aggregation, or misfolding due to factors like poor sequence design and choice of vector, contamination, less-than-ideal reagents, and experimental conditions.

Process of Recombinant Protein Expression

Recombinant protein is made by inserting the gene for the desired protein into a vector and then having the vector expressed in a model organism. People often use expression vectors that have a copy of the target gene to boost gene expression. The cloned gene can be expressed with the help of the vector’s powerful promoter.

Antibiotic resistance genes are put into expression vectors to make choosing the vector and the recombinant protein easier. Eukaryotic proteins can be synthesized in bacteria with the help of expression vectors. The vector includes a powerful, regulated promoter, terminator sequences, and the ribosome-binding site.

A cDNA is a transcript of the mRNA found in eukaryotes. When cloning ends, the plasmids are put into cells that can make more copies and store them.

Protein Synthesis Procedures

Molecular biology explains that there are two phases to protein synthesis in a cell: Transcription and Translation. This means Transcription and Translation are expression steps for recombinant proteins.

A gene is isolated and cloned into an expression vector to produce recombinant proteins. The protein expression, purification, and identification systems are required to produce recombinant proteins.

Fundamental steps to obtain recombinant protein:

- Amplification of the target gene

- Insert into a vector for cloning

- Subcloning within an expression vector

- Transformation into a host that expresses the protein (bacteria, yeast, mammalian cells, or baculovirus-insect cell system).

- Conduct an identification test on the recombinant protein.

- Large-scale fermentation or production

- Isolation and purification

There are many things to consider, for instance, which host system to use and how to separate and purify the recombinant proteins.

When choosing an expression host and a purification method isn’t easy because you have to think about the properties of the recombinant protein you want to make.

Below are some of the crucial factors to consider:

- Membrane-bound

- Solubility

- Single or multiple domains

- Molecular weight

- Expression site

For those who need more experience in expressing and isolating recombinant proteins, recombinant protein production is typically time-consuming. Many biological companies do a great job expressing different kinds of recombinant proteins on different scales. (See the complete list of recombinant protein production services)

Method of Protein Synthesis

When the recombinant protein sequence encodes a rare tRNA, protein synthesis slows. This can sometimes be fixed by adding rare tRNA to the translation process or moving to where the rare codon wobble resides.

Aberrant folding of recombinant proteins can lead to the formation of inclusion bodies. Molecular chaperone proteins hold the recombinant protein in place during Translation. This makes sure that the new polypeptide will fold correctly and usually work. The recombinant protein is more stable when made with a molecular chaperone that helps the protein fold correctly. On the other hand, the protein can be removed from the inclusion bodies, and refolding can be tried.

It is common practice to clone the intron-free, coding-sequence-only cDNA rendition of eukaryotic genes, as bacteria cannot process introns. Also, the cDNA version of the gene is usually used even when eukaryotic cells are being used.

Challenges and Opportunities of Recombinant Protein Production

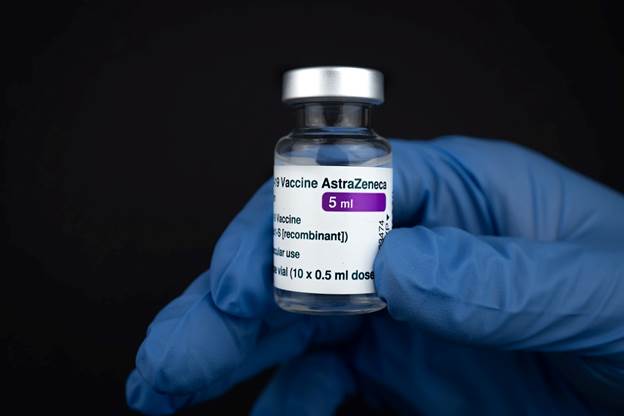

Therapeutic recombinant proteins are an effective weapon against many diseases that were previously difficult to treat. The most commonly used expression systems are derived from Escherichia coli and Chinese hamster ovary cells. However, the other expression systems have advantages and disadvantages regarding development expense, time, growth conditions, regulatory approval, protein size, yield, and post-translational modifications.

As more applications that require a large number of proteins enter the market, the efficient methods used by recombinant protein production services are becoming increasingly important. A commercially viable process requires high production efficiencies and a low final product cost. Here are some of the difficulties and potential benefits of recombinant protein expression.

Potential Benefits or Opportunities

The therapeutic protein market is vast, with players like enzymes, vaccines, antibodies, and hormones. Since every recombinant protein has production challenges , peptide synthesis companies must overcome challenges to ensure antibody specificity. That matches expression system strengths.

High-yield transient expression systems like Magnification produce protein faster from sequence to grams. Plants have the most significant advantage over other expression systems. This makes vaccines for bioterror threats and influenza possible. This technology also allows small production runs for orphan diseases with personalized treatments or very few patients. When combined with the ability to grow transgenic plants in low-cost greenhouses, the high cost of protein drugs for rare diseases could be significantly reduced.

Patents will expire as the therapeutic market matures, allowing the production of “biosimilars” or licensed protein copies. In the field or greenhouses, with proper containment, plant expression systems like a high-yield chloroplast expression system can produce proven drugs at a lower cost.

Plant glycoengineering does not yet have human-like N-glycosylation, so therapeutic proteins do not need it. However, engineering has made possible in vitro glycosylation, glycosylation pathways, and plant-produced N-glycosylated therapeutic proteins.

Lack of regulatory approval hinders plant expression system adoption. Veterinary, diagnostic, and medical devices made from plant-produced recombinant proteins do not need to meet the drug’s high human-use standards. Plant-produced therapeutic proteins aren’t worth the cost and difficulty of approval.

Plant expression systems are cost-effective and scalable. Plants produce protein cheaper than mammalian cells, but this has little effect on the cost of therapeutic protein drugs. Product purification costs more for custom antibodies. Mammalian and plant cell extracts are similar. The economic benefit would be more significant if plants purify and harvest protein at a lower cost, possibly through the expression target to some storage bodies.

Plants do not produce endotoxins or support viruses or prions that could infect humans, making them safer than other expression systems.

Challenges

The environment of genetically modified crops is one of the biggest problems with solid-phase peptide synthesis and plant protein expression systems. People are worried that recombinant genes will spread through pollen, seeds, and horizontal or viral transfer. Therapeutic proteins could end up in the food that people or animals eat, and that will hurt the animals and plants in the environment. Not too long ago, the USDA passed a law in response to the fact that some food crops had been found to contain transgenic plants. Using ELISA kits to check for exposure to viruses and other disease-causing organisms has shown that the environment is highly contaminated.

The special enzymes attached to antibodies in a person’s blood are used in Elisa’s tests. Getting rid of these worries is possible in several ways, for instance, by keeping them in one area and planting them at different times than local food crops.

The loss of expression is another problem. In custom gene synthesis, the right number of recombinant proteins must be made by making the gene of interest work well. The problem is that expression can be lost if the recombined genes’ structure changes or genes from the host cells are lost.

Conclusion

The relative expression of numerous functional gene components can be precisely controlled with cell engineering technology, impacting protein yield. Additionally, using novel protein forms, like bispecific antibodies and fusion proteins, paves the way for therapeutic applications. It is essential to producing high-quality RTPs that the contributors to the critical characteristics of RTPs throughout CHO cell culture are understood. The complexity of assembling these new RTPs may reduce their effectiveness and productivity.

We can start with the molecular design of proteins and add the appropriate cell line, vector engineering, and process optimization based on what we know about how proteins fold and where they might get stuck. This will allow us to improve protein secretion and prevent clumping, obtain the highest yield of recombinant proteins, keep large-scale production costs low, and encourage the development of biopharmaceuticals.