Recombinant Protein Expression Systems: Challenges & Opportunities

Aug 12th 2022

Many tools are available to generate recombinant proteins in different expression systems. The most commonly used systems include prokaryotic, eukaryotic, viral/phage, and baculovirus expression platforms. Each platform has its benefits and challenges for efficiently producing recombinant protein.

Therefore, improvements in current protein expression techniques are essential to make pure and stable recombinant proteins for pharmaceutical development. However, with each improvement comes new issues associated with custom antibodycost, safety, and environmental impact that systems developers must address.

This review considers the present status of systems used for the high-throughput expression of recombinant proteins, their opportunities, and their ability to meet production challenges.

What are Protein Expression Systems

Protein expression systems are genetic constructs that allow scientists to express proteins in a host organism. In other words, recombinant protein expression systems are a range of methods that enable scientists to produce and study proteins in a lab setting. This is done by inserting the gene for the protein into the host organism's genome and then allowing it to grow and express the protein.

But one might ask, what is recombinant protein?

There are two effective recombinant protein production systems: fermentation and genetic engineering. Fermentation is the oldest type of protein expression system, and it involves growing bacteria in a vat with nutrients and then extracting the protein from them. Genetic engineering involves inserting DNA into an organism's genome using recombinant DNA technology.

There are three different types of protein expression systems:

- Eukaryotes: These are composed of many other parts, including DNA, RNA, and organelles.

- Prokaryotes: These have a single circular chromosome with no internal membrane structure.

- Plasmids: These are small circular DNA molecules that replicate independently from the main chromosome.

Challenges Faced During Recombinant Protein Expression

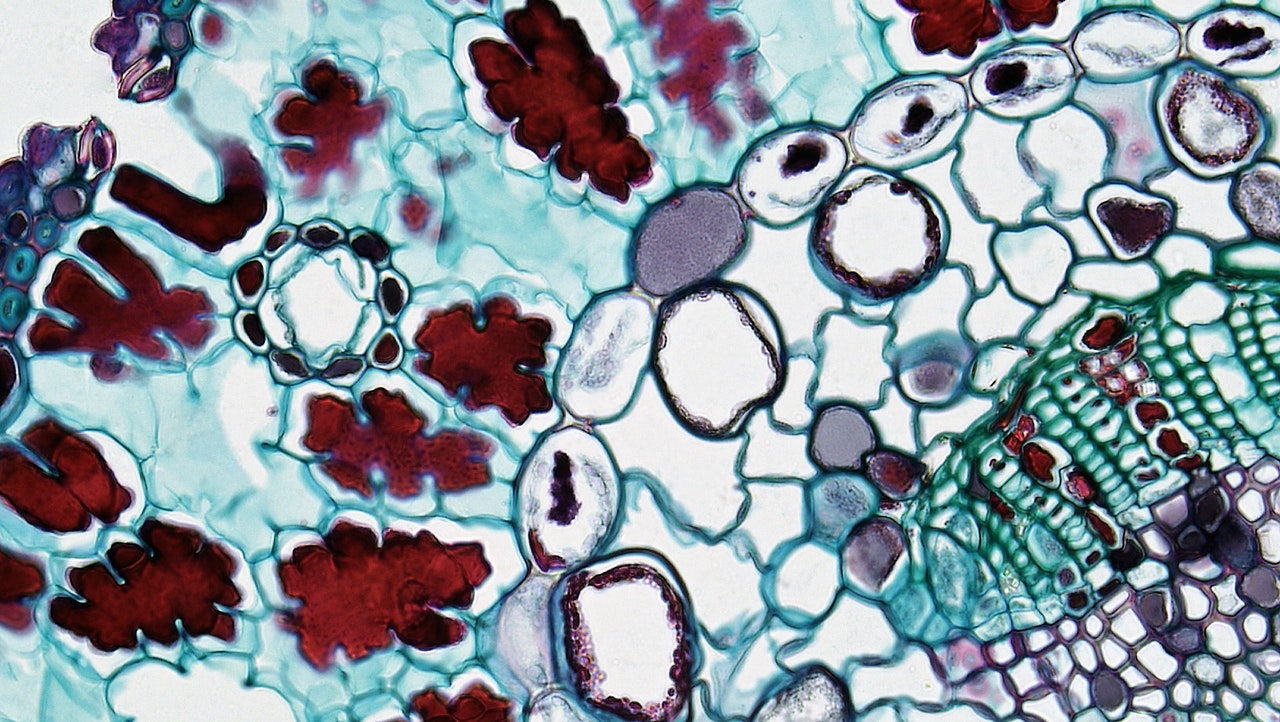

Photo by

Chokniti Khongchum

Many obstacles need overcoming before hosts can be used widely to express therapeutic proteins, even though utilizing each host may seem appealing.

Approval from the Regulators

Despite how promising this technology might be, pharmaceutical companies are hesitant to take a chance on spending the enormous sums of money necessary to get a new product approved by the significant drug authorities if there is already a tested alternative expression system that has received regulatory approval. The pharmaceutical business is experiencing a stalling impact due to this economic constraint, which limits the size of progress and the development of new technologies for the production of drugs. Due to the great degree of assurance required in every therapeutic molecule before it can be utilized on humans, unfortunately, this predicament is not something that can be avoided.

Because there are fewer regulatory barriers, the development of animal vaccinations in plants is moving more quickly. This could serve as evidence for the development of human vaccines in plants and highlight the significance of the expression system in producing therapeutic proteins efficiently.

Environmental Contamination

Concerns about genetically modified (GM) crops are perhaps the most significant obstacle to expression. Gene transfer in gene synthesis services by seed dispersal, pollen dispersal, viral transmission, or horizontal transfer are all crucial causes of worry, as are therapeutic proteins entering the food chain for humans or animals, as well as the potential harm they could cause to other creatures in the environment. In recent years, the USDA act was established in response to transgenic plants being discovered in food crops.

There are several ways to ease these worries, such as geographical containment, planting GM crops at different times than local food crops, using male sterility in GM plant strains, using the chloroplast expression system, using inducible promoters, making easily recognizable plant varieties, using self-pollinating species, making seeds that don't germinate, and making inactive fusion proteins that are initiated by steps of protein purification. It is possible to provide an efficient and cost-effective method for containing genetically modified plant material by cultivating crops in hydroponic growing rooms. These greenhouses are correctly controlled using cell suspension cultures.

Protein Stability

Concerns regarding the stability of produced proteins substantially influence the expression system's overall viability. Depending on the recombinant protein being expressed, there are different ways to stop unstable proteins from breaking down. Some of these ways are: making fusion proteins with a relatively stable peptide synthesis service with the therapeutic agent (this method can also make downstream processing easier with the use of affinity tags); targeting proteins to seeds, oil bodies, or protein storage vacuoles; freeze-drying plant matter to keep expressed proteins stable, and using a recombinant protein that is more stable.

Unexpected Biological Changes

Photo by

Chokniti Khongchum

For research projects and medication development efforts to be fruitful, having access to starting materials such as recombinant proteins of high quality is essential. Purity, oligomeric state, thermal and chemical integrity, folding, posttranslational modifications (PTMs), and functionality are some of the most important characteristics determining the quality of any recombinant protein. The protein manufacturing process and purification are notoriously tricky, primarily because of the inherently complicated nature of proteins. A protein's sequence or structural properties can affect the amount of recombinant protein produced and its capacity to remain stable.

For example, including transmembrane domains or GPI-anchor sequences frequently results in the attachment of target proteins to the plasma membrane, reducing the amount of protein that may be produced. In the meantime, the fact that transmembrane domains are not water-loving also affects how stable they are. While purifying these proteins and formulating new products, it is frequently necessary to use a detergent or a lipid-based stabilizing reagent.

On the other contrary, if the target protein is over-expressed and builds up, it might cause the host cells to change in ways that aren't expected. This could lead to the production of proteins that don't fold right and protein degradation by the host proteases.

Posttranslational Modifications

Many proteins can be co-expressed simultaneously in plants, allowing for complicated glycosylation engineering, making the plant proteome adaptable for complex protein synthesis processes ( Margolin et al., 2018). Although humans and plants share a similar glycosylation mechanism, there are significant differences in the N-glycan composition of the two species. The most notable of these distinctions is the addition of 1-3 fucose and 1-2 xylose, as well as the lack of 1-6 fucose, glucose, and sialic acid residues (Obembe et al., 2011).

These variations can significantly impact the distribution of therapeutic proteins, the half-life of the protein in serum, their activity,and their immunogenicity ( Twyman et al., 2003). Even though some safety concerns may not be warranted (Ma et al., 2003), no question producing therapeutic proteins with constant human-like N-glycosylation is an important goal. Some examples of these proteins are found in monoclonal antibody production. Proteins that don't require such specialized posttranslational modification may be better suited for plant synthesis than therapeutic proteins.

The issue of nonhuman N-glycosylation has been addressed in several ways, including in vitro modification using purified human 1-4 galactosyltransferase and sialyltransferase enzymes, knocking out or down native plant fucosyltransferase and xylyl transferase enzymes, and expressing human 1-4 galactosyltransferase in transgenic plants, according to Blix ( Bakker et al., 2001).

Plants can manufacture recombinant viral structural proteins easily. However, viral glycoproteins provide a barrier comparable to glycoproteins found in recombinant protein expression in mammalian cells. The problem of glycosylation, while challenging, is not unsolvable: plant-derived influenza haemagglutinin, the only viral glycoprotein to have been evaluated in humans, has been successfully engineered with glycans at all possible sites and is expected to have FDA approval by 2020.

Opportunities in Recombinant Protein Expression

As was already noted, developing a viable method to generate high-quality target proteins requires a methodical optimization effort/ Unfortunately, there is no "one-size-fits-all" strategy, and each recombinant protein expression and purification must be carefully tuned. Here, we'll utilize a few case studies to illustrate how to optimize essential steps in the workflow for recombinant protein formation.

Culture And Vector Conditions

Vectors can be considered vehicles that transport the genes of interest into the host cell. They include fundamental elements like an MCS to house the target gene, a promoter to boost expression, and antibiotic resistance genes to allow the screening. Vectors are usually improved by companies that sell them to work best for transfection and expression. As demonstrated, a vector system outperforms various competitors regarding recombinant protein expression in HEK293. In addition to vectors, other variables of the host cell culture, such as time and temperature, should be tuned to acquire the target protein in its native state. Meanwhile, introducing additives can occasionally aid the production of the target protein. Due to their stabilizing effects on the protein molecules, including inorganics such as metal ions and co-factors is beneficial for producing active enzymes.

Suitable Host

Photo by

Edward Jenner

The host cells decide how the recombinant protein might fold and its PTM pattern. You should carefully choose the host cells depending on the characteristics you want. The target protein's capacity to form coherent oligomers was of particular importance. Although the protein was first produced in insect cells, larger molecular weight polymers were discovered during purification.

Even though the formulation buffer was optimized, the polymers could not be removed. As a result, the expression host was changed for recombinant protein expression in Escherichia Coli. The protein produced by the first E. coli strain was easily degraded. Then, the second strain of E. coli was used, which had its endogenous protease knocked out for a longer time. Oligomerization of the target protein was achieved in this strain.

Protein Structure

Target proteins may have structural properties that could lead to instability in overexpressed recombinant proteins. It is essential to note areas with heightened hydrophobicity, high disorder, and repeated amino acid motifs because they are renowned for generating protein instability. It is possible that removing these areas can assist increase the amount of protein that can be produced.

Purification Procedure

The environment in which a protein resides directly impacts its ability to function. Alterations to the pH, ionic strength, and oxidative state would affect the stability of proteins. This general rule of thumb should be considered when searching for the buffer formula that will work best for protein purification or protein storage. Occasionally, chemicals are required during purification to stabilize the target protein or enable tag exposure.

A modification to the detergent formula improved the efficiency of protein extraction. During the final polishing stage, a different detergent called DDM was employed to consolidate the final protein product in place of detergent formula 2, which was also used.

Going High-all-the-Way

As was previously said, improvements in high-throughput screening call for a flexible high-throughput antibody/protein expression platform to aid in drug development progress. On the other hand, the COVID-19 pandemic highlighted the power of RNA viral hyper-mutation, and adequate technologies are required to construct mutant virus protein libraries to assist in the screening and evaluating of neutralizing antibodies. To aid in discovering new medicines and studying infectious diseases, experts have developed a high-throughput platform for creating recombinant antibodies and proteins.

The HEK293 serves as the foundation for this platform. A PCR-based approach generates a custom antibody/protein sequence library, which is subsequently transferred to HEK293 cells for expression. Purified antibodies/proteins are submitted to quality and activity evaluations, with the most promising candidates proceeding to scale up. Flasks are the primary culture technique in this system, and it is possible to manufacture 100–200 molecules per week based on the volume of each culture.

A library of up to 600 antibodies has been successfully generated using this platform in over a dozen applications. This platform has also been used to manufacture virus proteins, including influenza HA and NA and SARS-CoV-2 RBD mutates, demonstrating the platform's adaptability.

Conclusion

There are several techniques presently in use for the production of recombinant proteins. However, no single approach is ideal for producing all proteins, and the differences arise from the various requirements of proteins produced.

With the help of technology and new strategies, scientists have overcome the challenges associated with expression systems. This has revolutionized the industrial production of proteins and opened doors for developers of new biopharmaceutical drugs. The successful implementation of cell factories in the worldwide market has enabled drug developers to meet the growing demand for recombinant protein pharmaceuticals, leading to a more promising future for the biotech industry.