Recombinant Protein Production: The Future of Biotechnology

Apr 4th 2023

Alt text – Recombinant Protein Production - The Future of Biotechnology

Recombinant protein synthesis within the system of a mammal has been a hot topic in biotechnology. This fast-growing discipline entails using biological mechanisms, living creatures, and their variants to create new products, methods, and techniques. Recombinant protein manufacturing, which uses genetically modified organisms to manufacture certain proteins for several applications, is one sector that has made considerable advancements in recent years. The biotechnology sector has already seen a significant impact from recombinant protein technology, particularly in creating therapeutic proteins for diagnosing and treating diseases.

Recombinant protein technology, however, has a wide range of possible uses, and its influence is only expected to grow. An optimum recombinant protein generation method must be chosen to create high-quality, effective recombinant proteins. This article will examine the recombinant protein manufacturing process, its benefits over conventional protein synthesis techniques, and its current and possible future uses in sustainability, industry, and medicine.

Recombinant Protein

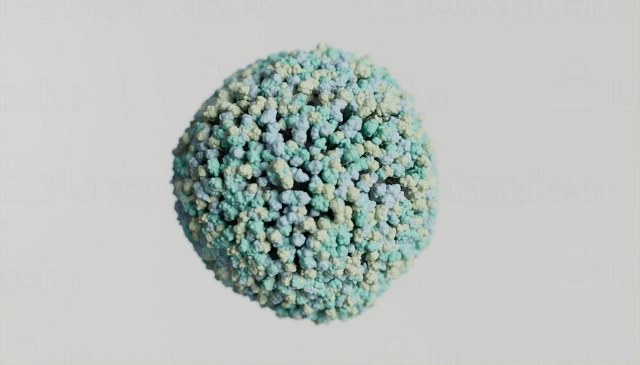

They are proteins made using genetic engineering methods that require introducing particular genes into host organisms, usually yeast or bacteria. The target protein is then produced by the host cells via these genes. Recombinant proteins have a long history that dates back to the 1950s and 1960s, from gene synthesiswhen the structure of DNA was discovered and genetic information was first understood. The first discovery of a recombinant DNA molecule, comprising genes from two distinct creatures, was successfully produced in 1972 by Paul Berg and his colleagues. This discovery opened the door for the creation of recombinant DNA technology, which completely transformed contemporary biotechnology.

Insulin was the first recombinant protein produced using recombinant DNA technology in 1978.

Insulin was the first recombinant protein produced using recombinant DNA technology in 1978. Before this advanced technology, insulin was extracted from the pancreas of either cows or pigs, which was an expensive and time-consuming procedure. The growth of recombinant insulin enabled insulin production in large volumes and at a lower price, which significantly helped people with diabetes. In the following years, scientists invented new techniques to help produce recombinant proteins. One of the most important scientific advances was the creation of enormous amounts of DNA to produce recombinant proteins.

A project called Human Genome was started in 1990 to sequence the whole genome of humans. This project contributed immensely to our knowledge of human genetics and created the foundation for fresh recombinant protein-based treatments. Examples of most frequently manufactured recombinant proteins include monoclonal antibodies, growth hormones, insulin, and cytokines. Since recombinant protein technology has developed and grown, it has been employed to generate various proteins for use in business, research, and healthcare.

Recombinant Protein Production

Recombinant protein production is an essential process in biotechnology and pharmaceuticals because it allows for the manufacture of valuable proteins for investigation, diagnostics, and treatment. It involves inserting specific genes into host cells, such as bacteria or yeast, to make them the desired protein. The process entails several steps that necessitate knowledge and experience in molecular biology, biological sciences, and protein biochemistry. The following Recombinant Protein production steps are involved in the process:

Cloning of Genes

The first step in producing recombinant proteins is isolating and manipulating the gene that generates the desired protein. A DNA molecule called an expression vector is then used to clone the gene; it contains the regulatory components required for the gene's expression in the host cell. The expression vector chosen is determined by the type of host cell used for protein production and the desired production level. In this case, the frequently used expression vector is a pET vector system intended to express bacteria using the T7 RNA polymerase promoter, facilitating high-level expression in the gene-targeting process.

Depending on the intended expression system, vectors like those built on baculovirus or animal cells may also be employed. Several techniques can be used to clone the gene into the expression vector, such as PCR amplification, digestion restriction enzyme, ligation, and Site-directed mutation. The selected technique depends on the gene's intricacy and the particular needs of the cloning method.

Transformation of the Host Cell

In this process, the expression vector is then converted into an appropriate host cell after the introduction of the gene. The selection of the host cell is influenced by several variables, such as the desired amount of protein expression, the protein's stability in the host cell, and the alterations in post-translational necessary for the protein to function. Yeast, mammalian, and bacterial cells are the common host cells used in this case.

Bacteria like E. coli produce small, soluble proteins, whereas yeast like S. cerevisiae can yield more complex proteins with post-translational modifications. The manufacture of therapeutic proteins that call for post-translational alterations resembling those made by recombinant protein production in mammalian cells, including Chinese hamster ovary (CHO) cells, is frequently employed.

Protein Expression

After the transformed cells are selected, they are cultured in environments encouraging protein expression. The best growing conditions depend on; the host cell type and the specific needs of the protein and are frequently adjusted for high-level expression of the target protein in bacterial expression systems. This may entail using a particular growing medium and adjusting the temperature, oxygen, and PH levels.

The culture conditions are often set up for generating correctly folded and post-translationally altered proteins in mammalian expression systems; they may involve utilizing serum-free media, adding particular growth agents, optimizing cell concentration and culture duration, and more. SDS-PAGE and Western blot analysis are two methods for observing the expression of the protein. These methods make it possible to identify and measure the protein of interest and may be employed to improve the growth conditions for the synthesis of proteins.

Protein Purification

After production, the protein must be cleansed from the host cell and all other contaminants. This can be a difficult and time-consuming process because the protein may need to be dissociated from many other proteins and chemicals in the host cell. Under the purification process, the following methods are used; chromatography (the common method), centrifugation, precipitation, and filtration. Chromatography involves the separation of proteins from other components based on their chemical and physical characteristics.

Proteins can be purified to a high degree using various chromatographic methods, including ion exchange, size exclusion, and affinity chromatography. Filtration can eliminate more significant pollutants, whereas centrifugation can separate proteins according to their size and density. By introducing a chemical substance to the protein solution, precipitation causes the protein to separate from the solution and allows for separation from other molecules. The protein quality, the size of the production process, and the desired degree of purification all influence the selection of the purification technique.

The Protein's Characterization

After purification, the protein must be categorized to ensure it is the appropriate protein with the ideal properties. Characterization techniques include mass, circular dichroism, and nuclear magnetic resonance spectroscopic analysis. The molecular mass of the protein and any post-translational changes can be determined using mass spectrometry. The secondary protein structure can be ascertained using circular dichroism spectroscopy, whereas the three-dimensional structure can be ascertained using NMR spectroscopy. To ensure the protein is of high quality for its intended use, it is crucial to characterize it.

Protein Preparation and Storage

The protein must be prepared and kept for its intended application after it has been isolated and categorized. Stabilizing chemicals, including buffers, salts, and sugars, are added to the protein solution to prevent protein deterioration and aggregation during formulation. The protein is usually maintained at a low temperature, like -80°C, to avoid breakdown and maintain protein stability. The protein's characteristics and desired use determine the storage conditions.

Antibody Services, Sequencing, and Sequencing Services

Each stage in the procedure is essential for successfully producing high-quality recombinant proteins. The synthesis, purification, and characterization of antibodies against a particular recombinant protein are called antibody service in recombinant proteins. This service can help with the creation of therapeutic antibodies as well as antibodies that can be utilized for research and diagnostics. Antibody Determine the sequence of the point mutation of the antibody that attaches to the recombinant protein to sequence recombinant proteins.

Using this knowledge, the antibody's binding capabilities can be improved, or new antibodies with higher specificity or affinities for the recombinant protein can be created. Businesses specializing in sequencing antibodies against particular recombinant proteins provide antibody sequencing services. These services often involve creating high-quality sequence information for research and development using cutting-edge technology, such as spectrometry or next-generation sequencing.

Enzyme-Linked Immunosorbent Assay

Science lab tools detect and quantify proteins, peptides, monoclonal antibodies, and other bioactive molecules in biological samples. ELISA Kits consist of a pre-coated microplate, certain antibodies, detecting reagents, and calibrating standards

Benefits Of Recombinant Proteins Over Traditional Protein Synthesis Techniques

The generation of recombinant proteins has several benefits over traditional methods of protein synthesis; chemical processing or separation from natural sources. The benefits include:

1. High Yields

Recombinant protein synthesis is perfect for large-scale production since it can generate sufficient amounts of protein. In contrast, it's possible that chemical synthesis or protein separation from natural sources won't yield enough of the substance. By using a host cell for manufacturing the protein, recombinant protein manufacturing enables the production of substantial amounts of protein.

2. Adaptability

Various proteins, such as those that are challenging to obtain using other techniques, can be produced using recombinant technologies. The creation of medicinal proteins, enzymes, and antigens is just one of the significant biotechnological applications made possible by this adaptability. The ability to create recombinant proteins has also made it possible to create proteins with particular modifications, such as protein fusion or proteins with certain post-translational modifications.

3. High Purity

The manufacture of pure proteins is made possible through recombinant technology, which is essential for various uses, such as research and therapies. However, proteins extracted from natural sources may have contaminants that reduce their effectiveness and safety. To create recombinant proteins, the protein out from the host cell must be purified, enabling extremely pure proteins to be created.

4. Highly Safe

The likelihood of negative consequences associated with proteins separated from natural sources is decreased by recombinant protein manufacturing, which can create proteins free of toxins and pathogens. Creating proteins that are hard to come by naturally or may be dangerous to obtain naturally can also be accomplished through a host cell.

5. Good Speed in Production

Recombinant protein synthesis can create proteins fast, with some being ready in a few hours. Applications like diagnostics and therapies, which demand a quick response, depend on this speed. Recombinant protein production is quick, allowing for the timely creation of proteins while reducing the time and expense involved in protein production.

Current and Possible Future Uses in Sustainability, Industry, and Medicine

There are several uses for recombinant protein synthesis in industry, medicine, and sustainability. In sustainability, it can provide substitute food sources, such as plant-based proteins, that help lessen the environmental effect of animal agriculture. In addition, recombinant proteins can be created to create biodegradable materials like bioplastics, which can lessen the waste produced by regular plastics.

In industry, enzymes can be used for pharmaceutical protein production and synthesizing biofuels and detergents through recombinant proteins. Moreover, recombinant proteins can make antibodies for therapeutic and diagnostic uses, such as cancer treatment and detecting infectious diseases. Recombinant proteins can help industrial manufacturing processes be more productive and environmentally friendly.

Recombinant protein manufacturing may also provide clean, renewable energy sources.

Recombinant protein production is already widely utilized in medicine to create therapeutic proteins, such as erythropoietin and insulin, for treating anemia and diabetes. Moreover, recombinant proteins can create vaccines and antibody treatments for cancer and infectious disorders. Recombinant protein manufacturing in medicine has transformed biotechnology and created fresh, cutting-edge cures for various ailments.

The creation of tailored medicine is one potential application for recombinant protein production in the future. It can create individualized medicines that are more successful and have fewer adverse effects by producing proteins that are specific to a person's genetic makeup. Also, there is a significant study into the use of recombinant proteins in regenerative medicine, including the creation of artificial organs.

Recombinant protein manufacturing may also provide clean, renewable energy sources. Recombinant proteins can be employed in biocatalysts to create more efficient and sustainable methods for creating biofuels and other renewable energy sources. Proteins can act as catalysts for various chemical process development actions.

Conclusion

Finally, recombinant protein generation has transformed biotechnology by enabling large-scale protein production with purity and consistency. This technology has created numerous life-saving forms of treatment and industrial products and cemented the way for new biotechnology advancements and developments. Biotechnology is expected to significantly contribute to society by developing new technologies and products that address some of humanity's most pressing challenges.

Genome editing, bioengineering, gene therapy, precision treatment, bioprocessing, and bioremediation are promising for addressing disease, climate variability, and food security issues. As we learn more about the biological systems that underpin life, biotechnology is likely to evolve and expand, bringing with it novel possibilities and difficulties in equal measure. However, with ongoing support and investment, biotechnology has the potential to improve people's health, as well as the health of the planet.