Everything You Need to Know About Custom Protein Synthesis

Sep 16th 2022

The need for recombinant proteins in biometrics and other domains has skyrocketed. While creating high-quality proteins can be challenging, the availability of protein expression services on a commercial scale has made the procedure more readily accessible.

Recombinant protein production begins with cloning protein-coding sequences into a suitable expression vector and then converting them into host cells. Custom protein expression is an essential component of recombinant protein synthesis.

This post will discuss all you need to know about custom protein production. We will also discuss the factors influencing soluble protein expression and how you can modify them.

What is Custom Protein Synthesis?

Custom proteins are recombinant proteins created by custom manufacturing rather than commercial production. But what are recombinant proteins? Recombinant proteins are made by cloning recombinant DNA into an expressional vector, which expresses the gene and translates the messenger RNA.

A custom protein can be produced by modifying a gene using recombinant DNA technology and custom DNA synthesis. Recombinant protein is a modified form of natural protein created in various ways to increase protein output, modify gene sequences, and make economically viable products.

Forms of Custom Protein Synthesis

Protein expression is a biological process wherein proteins are produced in cells using artificial genetic material derived from molecular biology. It is the process through which proteins are generated, changed, and controlled in living organisms. Custom protein expression refers to the laboratory procedures required to create proteins in protein research.

Proteins are generated in response to the cell’s functional requirements. The selection of an appropriate protein expression system is critical to the success of recombinant protein production. Several variables must be considered when choosing a protein expression system; several variables must be considered, including cost, protein production, and intended use.

During the expression process, each protein has a distinct biochemical property. Protein expression services entail custom gene synthesis, protein purification, codon optimization, vector designs, and protein quality control testing. Other expression services include protein labeling, endotoxin removal, and protein interaction analysis.

Custom protein expression relies heavily on high-quality antibody production. When selecting an expression system for Production, it’s best to consider several factors, such as desired yield, protein type, and functional activity. It would help if you also learned how to use Elisa kits to improve protein output by enhancing overexpressed protein expression and solubility.

Key Facts to Know About Custom Protein Production

1. Amplification of Genes

The differential growth of an individual genome's segment relative to the remaining portion is referred to as gene amplification. This is a common mechanism in most organisms and has been shown to occur in somatic and germline cells. Gene amplification is mainly linked to normal developmental processes. They may also arise as occasional genetic events with either negative or positive effects on the organism.

Human tumors have been researched for somatic cell gene amplification. Gene amplification was identified as a physiological activity during the development of Drosophila melanogaster. To survive under stress, mammalian cells primarily employ the method of gene amplification to overexpress specific genes. When exposed to cytotoxic medicines, for example. Four models for the formation of amplifications have been proposed. They are as follows:

2. The Right Expression Vector Can Impact Protein Solubility

A vector for gene expression inserts a particular gene into a target cell. The DNA molecule in the host cell contains a specific gene and utilizes the cell’s protein synthesis machinery to generate the protein. Due to the significance of expression vectors in the Production of recombinant proteins, the expression system-optimal expression vector must be used. The vector must be system-specific.

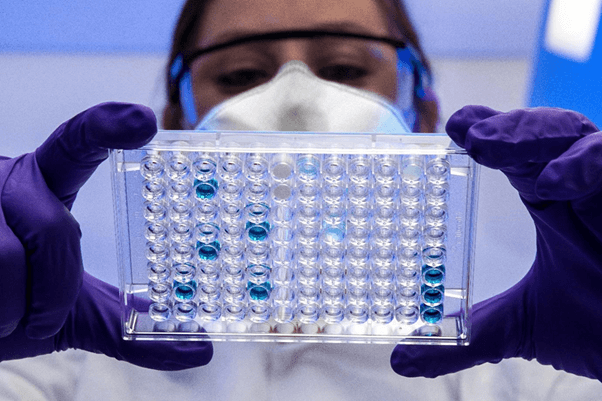

Several aspects must be considered when selecting an expression vector for bespoke protein synthesis. First, ensure that the vector has the required components for gene expression. Additionally, it should have a purification tag for the whole purification procedure. It is often vital to understand how to do an ELISA test to discover which generates the highest yield of soluble proteins.

In most instances, the expression vector for protein synthesis includes a purification tag that facilitates protein purification service once the expression process has concluded. In addition to the purification tag, they may consist of other tags and fusion proteins to aid in understanding the function and interactions of the target protein.

Consider the promoter strength while selecting an expression vector. The suitable promoter should be strong enough to allow for substantial product accumulation in host cells while limiting adverse effects, such as toxicity, on cell development. A strong promoter is required for optimal protein output, while a cold-shock promoter is ideal for aggregation-prone proteins expressed at low temperatures.

When choosing a promoter system, consider the nature of the protein target and its intended purpose. Utilize promoter systems with insufficient basal expression while combating their harmful protein.

When selecting an appropriate expression vector, you should also consider its size. For this procedure to be successful, relatively tiny molecules must be used as vectors to facilitate manipulation. Large vectors may impair replication and stability because they collect and fold more slowly. By including folding catalysts into E. coli protein synthesis, aggregation may be prevented, and folding can be facilitated. This permits the target to be encoded using a second protein discovered on the same or a different plasmid.

3. Modify Expression Conditions to Improve Protein Solubility

During custom protein expression, the expression circumstances might impact the overall protein manufacturing sequence. For instance, replication and transcription rates are affected by high expression temperatures.

Utilize strong expression promoters to initiate protein aggregation before folding. It may be necessary to limit translation and transcription rates to enable folding. By decreasing these rates, protein synthesis may complete before the formation of aggregates.

Use low expression temperatures to increase the solubility of the recombinant protein. Low temperatures assist in slowing down cellular activities, hence decreasing the rates of transcription, translation, and protein aggregation. Additionally, reducing the temperature lowers the loss of custom antibody sensitivity. In contrast, elevated temperatures may alter the rates of protein translation, replication, and transcription.

Another technique is to reduce the concentration of the induction agent. This reduces transcription rates and may have a function in enhancing the solubility of the recombinant protein. Additionally, the medium you choose may improve the solubility of proteins. Organizations often grow cells for recombinant protein production using batch culture. Ensure that the growing media has sufficient nutrients to promote development.

4. Protein Purification is Vital for Custom Protein Expression

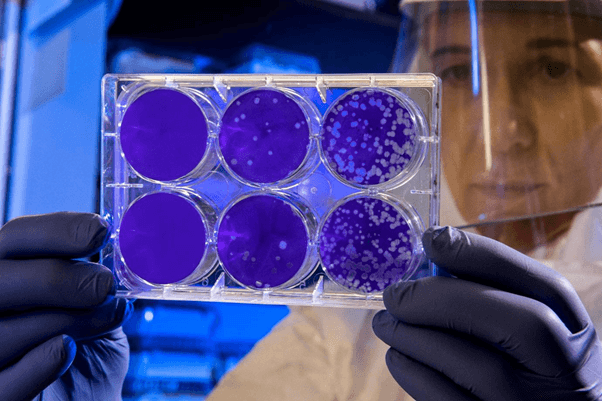

The protein expression and purification services characterize the protein’s function, structure, and interactions. During the purification procedure, proteins and non-protein components of a mixture are separated to achieve the required quality.

Since each protein is unique, its intended use should determine the purification technique for each protein. Either native or denatured conditions may purify the protein using glutathione. IMAC will be used for custom protein expression in the initial stage of synthesizing antibodies. Incorporate size-exclusion chromatography before the ion-exchange chromatography if the procedure requires extra purification.

When purifying the expressed protein, an additional affinity tag is used. This will guarantee that proteins are soluble after expression purification under non-denaturing conditions. The residual proteins are then solubilized and purified under conditions of denaturation.

5. Adding a Stability Sequence can Enhance Production

A stability sequence optimizes the manufacturing process by generating a buffer solution. It may also increase the solubility of amino acids and protein polymerization. Adding a stability sequence to the custom protein synthesis helps to stabilize the production of unstable proteins and enhances their purification.

Use several tags to increase the solubility and purifying efficiency of proteins. Using fusion tags during the synthesis of proteins enhances their solubility without altering their folding. For instance, fusion tags may be added to the C- and N-terminal protein regions. You may also employ peptides containing amino acids to address problematic protein solubility circumstances. Antibody sequencing services assist in resolving stability issues by enhancing amino acid aggregation, solubility, and polymerization.

Usually, the beginning and ending residues of the target domain may alter protein solubility and expression yields. Utilize functional and structural information to establish the best domain construct boundaries during protein expression. Attach the protein sequence to a homologous protein structure to find the best domain borders if a protein’s domain structure is unknown.

6. Use Codon Optimization to Deal with Rare Codons

This is the primary and most frequent reason heterologous proteins cannot express uncommon codons in the target mRNA. When the codon frequency of the target gene differs from that of the expression host, translation may halt or be prematurely terminated.

Gene synthesis companies can eliminate codon bias by using codon optimization gene synthesis services. Using a synonymous codon modification to promote protein solubility is the strategy. It provides benefits, such as the opportunity to alter the codon bias of a gene to make it compatible with the recombinant host.

Codon optimization involves substituting unusual codons with common codons while keeping the sequence of amino acids. Optimizing a gene of interest in a particular heterogeneous expression system can increase its translation rate and overcome constraints caused by variations in codon use. Custom DNA synthesis is a method for codon optimization that helps avoid codon bias problems during heterologous protein production.

There are E. coli expression strains with unusual tRNAs that assist overcome the codon bias of recombinant genes. This occurs when using the natural resource president in tRNAs increases protein abundance. A vector design optimized for antigen synthesis guarantees the development of monoclonal antibodies.

Increasing molecular weight may also influence the solubility of proteins during recombinant protein synthesis. Using E. Coli as an expression host necessitates the design of individual protein domains rather than whole proteins. Consider using solubility-enhancing fusion tags since they aid in the purification of proteins without interfering with their biological or biochemical functions. Considering that fusion tags may occasionally interfere with the biological function of a produced protein, it may be prudent to enzymatically remove the tag once the official portal has been purified.

5 Benefits of Custom Protein Production

1. Optimally managing your suppliers.

You may customize your quality control by selecting a customized protein service provider who will let you know where and by whom your protein is made (QC). Protein production must correspond to your criteria, and you can be sure that the subsequent batches will do the same. Low batch-to-batch variation guarantees production consistency and the repeatability of your results. In other words, how can you be confident that the source of your present supply is the one that is producing and will continue to do so? These problems can be solved by selecting custom protein expressions.

2. Reproducible biological operation

Batch-to-batch volatility is reduced by years of production experience with a specific source. There is no possibility of supplier changes, which is an issue with OEM items. You save time, money, and effort by avoiding protracted batch validations, but things get worse when the batch doesn’t fit, and you must find and revalidate new vendors. However, it’s important to note that biological testing has not been done on proteins. Therefore, if you don’t research, you run the chance of spending time and money on an antibody production service that won’t meet your requirements.

3. It reduces costs

Custom protein makers offer significant financial savings. However, a custom batch is less expensive after the initial fabrication if your activity requires enormous quantities of proteins. The Production also provides volume flexibility to decrease costs while meeting expanding demand. If you frequently buy recombinant proteins, comparing your prices to those of a custom producer might be advantageous.

4. It makes your project more flexible.

How often have promising projects been shelved because the reagents were too expensive? This problem frequently arises in conventional recombinant manufacturing, although custom production services and solid-phase custom peptide synthesis procedure doesn’t. As your research develops, you can decide to produce modifications of a wild-type protein.

5. It is biotherapeutic

Most diseases are caused by problems with proteins in the body as a whole or in large parts. Therapeutic proteins are essential treatments for various conditions, such as diabetes, cancer, infectious diseases, hemophilia, and anemia. Therapeutic proteins include antibodies, Fc fusion proteins, hormones, interleukins, enzymes, and things that stop blood from clotting. Human proteins made through genetic engineering are essential to the medicine market.

Conclusion

A protein expression system is used to produce recombinant proteins of high quality. Due to a rise in the number of service firms and developments in synthetic biology, bespoke protein expression has become more inexpensive today. The sophisticated protein expression optimization technique has also helped optimize protein production and purity.

This post has provided information on custom protein expression. Various aspects must be examined while deciding which expression system to use. Choose the appropriate expression host and expression vector for recombinant protein synthesis services. There are commercial peptide synthesis firms that help with custom protein expression. These businesses have expertise in recombinant expression and custom antibody production.