Identifying and Avoiding Mistakes in Antibody Production

Jan 17th 2023

The use of antibodies is pervasive in the biological sciences. Finding the finest research procedures, nevertheless, has not been simple. Numerous widely deployed antibodies and antibody conjugates lack good endorsement and are ineffective. The dilemma of reproducibility in biomedical research has been exacerbated by the uncritical deployment of such ineffective technologies.

They can theoretically be used in nearly every field, but in practice, it is more complex than one may erroneously anticipate. Antibody-related merchandise still has improper validation and access to crucial empirical observations. This article will go over the steps involved in creating antibodies, the faults that can happen, and potential fixes that could assist in creating high-quality antibodies.

Production of Antibodies

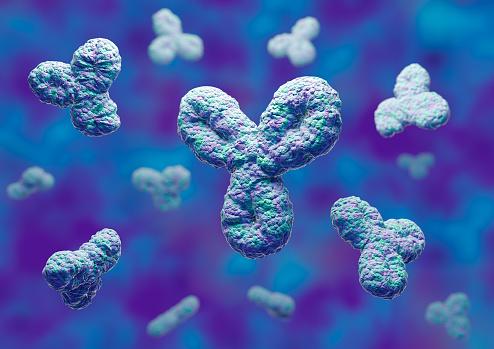

What is antibody production? The phrase "antibody production" has both broad and detailed connotations. In a broad sense, it refers to all steps involved in producing particular antibodies, such as those involved in immunogen synthesis, vaccination, the creation of hybridomas, screening, and purification. Antibody production definition solely refers to the steps in antibody production. There are several approaches for producing antibodies as a result of technological advancements. Hybridoma cells can be used in vitro to make monoclonal antibodies. The majority of polyclonal antibodies are produced in rabbits.

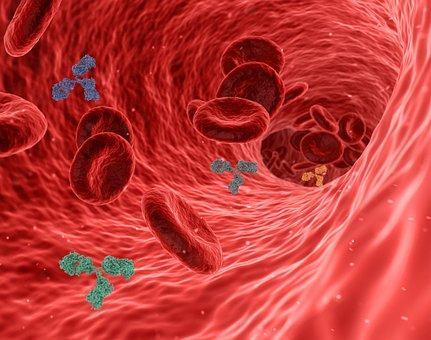

The generation of antibodies characterizes the immune system's adaptive reaction. The purpose of antibodies is to disarm or get rid of infections or antigens. B lymphocytes (b cells) generate antibodies after differentiating into plasma cells. Animals immunized against a chosen antigen can aid in polyclonal antibody production (PoAbs). There are several quantitative, forensic, and pharmacological uses for PoAbs. PoAbs have been employed to stop illnesses like diphtheria since 1894.

The wide range in adherence and selectivity across various batches of PoAbs is a significant drawback of employing these antibodies. A supplement injection must be provided to the animals before each PoAk harvest. The development of monoclonal antibodies solved these PoAbs' disadvantages (MoAbs). Kohler and Milstein were the ones to find MoAb. The steady supply of antibodies with reliable selectivity and affinities comes from MoAbs. In addition to revolutionizing the area of immunodiagnostics, the breakthrough of monoclonal antibodies had significant positive effects on medical research. MoAbs are often employed in business, scientific research, and therapeutic medicine.

Preparing antigen samples and safely injecting them into farm or laboratory animals result in significant levels of antigen-specific antibodies being expressed in serum, which may subsequently be retrieved from the animals. Polyclonal antibody production begins with serum (blood sample). Monoclonal antibodies are created by combining immortalized myeloma cells with antibody-secreting splenocytes from vaccinated mice to create a monoclonal hybridoma cell line that expresses particular antibodies inside the cell culture supernatant.

Peptides also play a significant role in antibody production. Therefore, before you start the antibody production process, you start with peptide synthesis. Produced antibodies can be used in the recombinant protein production process.

Antibody Purification

Antibody purification involves the isolation of specific antibodies from the serum for polyclonal antibodies, cell culture supernatant, or ascites fluids of the hybridoma cell line for monoclonal antibodies. Antibody purification methods are classified, ranging from very crude to highly specific. These classifications include;

- Physicochemical fractionation includes size exclusion, differential precipitation, or solid-phase binding of immunoglobulins based on charge, size, or any other shared chemical features of antibodies in a given sample. These methods help isolate any subset of sample proteins, including immunoglobulins.

- Class-specific affinity- this method helps to purify all antibodies of the required class without considering antigen specificity. For example, solid-phase binding of given antibody classes such as IgG by immobilized biological ligands, e.g., lectins and proteins, among others, which have a specific affinity to immunoglobulins.

- Antigen-specific affinity- antibody purification involves affinity purification of those antibodies found in a sample that bind to a specific antigen molecule using their specific antigen-binding domains. It helps purify all antibodies that bind the antigen without considering antibody isotype or class.

Antibodies produced as supernatant or ascites fluid and developed as monoclonal antibody hybridoma cell linens can be purified without necessarily using an antigen-specific affinity method. This is because the needed antibody is the only immunoglobulin in the sample (this is common for practical and experimental purposes). Contrary to polyclonal antibodies (serum samples), you can use the antigen-specific affinity purification method. This helps to prevent possible co-purification of nonspecific immunoglobulins. For example, the mouse serum only contains 2-5% of the total IgG for specific antigens used in immunization. This degree and type of purification are essential to extract usable antibodies.

Some standard methods used in antibody purification include; Size exclusion chromatography, Ammonium sulfate precipitation, Ion exchange chromatography, Immobilized metal chelate chromatography, Thiophilic adsorption, and Melon Gel chromatography.

During antibody purification, possible mistakes can happen, affecting the quality of the produced antibodies. Antibody purification is essential in ensuring the production of pure antibodies with no contaminations.

The use of the wrong purification method and reagents are some of the mistakes that can happen during the purification process. To avoid such mistakes, it would be good to research the best purification method for a given antibody or consult experts. Also, using the three classifications of the purification methods, ranging from crude to highly specific, you can identify which method is suitable for your antibody. Another possible mistake during purification is impatience, failing to give your sample enough time to go through the process.

Errors Made in Antibody Production

1. Contamination of Production Materials

Average temp and contamination are two fundamentally preventable issues in antibody synthesis. Temperature changes and stressors on cell lines might result from improper specimen handling throughout transit and in cells. Thus, strained cells can significantly impair antibody production, necessitating much work to restore the cell line to productive proportions. The effectiveness of the operation and the infrastructure are maintained by careful sample preservation throughout the transit phase, which guarantees an ideal temperature.

Scientists warn that antibodies may cross-react with proteins other than their primary targets and need to be more precise to be used in their application area. Over the past 30 years, mycoplasma fouling and other adventitious agents have evolved into a lesser danger, but they are still a concern. Whenever contamination happens, it isn't always visible. However, once the cell culture starts to decline, it can significantly influence productivity by changing how cells behave and function.

The risk of contamination can be reduced by using well-documented laboratory techniques, tested medium and supplementation from reliable vendors, and appropriate cell and apparatus segregation. Extensive affirmation may establish antibody specificity, enhancing the caliber and repeatability of study findings. Rigorous validation of the antibodies employed in the creation of the test assures excellent assay specificity and speeds up the process of providing patients who require them with appropriate medicines.

2. Inability to Wait Patiently Throughout the Manufacturing

Specific cell lines are first established to address a research topic for a short-term endeavor. The cell line is then assessed for its economic viability as it gains profitability. However, their output could be at risk if cells were produced quickly or incorrectly to achieve an optimal synthesis. In this scenario, either the customer will be left with a cell line which might boost their manufacturing cost, or the cell line will need a lot more resources and time to function optimally.

During these circumstances, laboratory patience is genuinely a positive attribute. It is advised that researchers start by giving themselves enough time to create their lines and strategically design a grand project for the cells. A cell line's potential for commercialization will assist direct advancement and may be used to choose the best development associates who can swiftly scale up to production levels.

3. The Utilization of Faulty Identifier, Validation, And Standardization Tools

An antibody can bind just the target utilized during vaccination. All too frequently, the vaccination approach is chosen without the involvement of the target population. As a result, industrial antibody makers have to assist the rising need for better methods for standardization and validation. The antibody production society should revive the ground-breaking standardization goals and update "Minimum information about a protein affinity reagent" (MIAPAR) and "Proteomics Standards Initiative-Protein affinity binders" (PSI-PAR) to create a more straightforward, conventional utilization framework for affinity binders.

By employing sound research procedures, the drawbacks of monoclonal antibodies and polyclonal sera can be significantly reduced sufficiently that the benefits exceed them. It is hard to ignore the importance of antibody sequencing services for reliable recombinant protein production. However, the scarcity of sequence information, relatively, is the unavailability of consistent evaluations of antigen binding. With suitable research methods, sequencing antibodies becomes more of a pleasure than a requirement in most use scenarios.

Additionally, it is crucial to correctly identify antibodies to prevent research findings from being unreplicable and merchandise confusion caused by the rebranding of individual antibodies. Antigen-binding subunit sequencing is only one method for giving the various binders a distinctive, long-lasting identity. Identifying preexisting antibodies in published papers will also be aided by other projects, such as the Research Resource Identifier (RRID). The medical and scientific society should strive to avoid fragmentation of enduring antibody identification and settle on a single identifier platform with standard protocols.

4. Unreliable Information Streams

Communication of as much material as possible must be done after a production partner has been chosen. Tell the partner what the product's ultimate aim is. Is this supply, for instance, only a feasibility test? Does this pertain to a commodity that will ultimately be implemented in the company to satisfy market needs? Will this item obtain a license and become subject to particular legislative compliance? These specifics assist the development partner in planning for expansion and being ready to gather necessary data for subsequent contributions.

The development partner must communicate promptly and effectively to keep their clients updated on concerns and accomplishments. For instance, if a customer expects cleansed material in 4 to 7 weeks and the development partner notices problems with the product, they must immediately notify any issues and handle the customer’s requirements.

Monoclonal Antibody Production Cost

The identification, optimization, production, and delivery of more effective, less expensive monoclonal antibody treatments should all be aided by technology advancements, according to a new paper from the Welcome Trust and IAVI.

The monoclonal antibody production cost is substantial, making it among the main obstacles to their supply in LMICs, as does their premium price. The quantity of mAb(s) per dosage, the regimen (the number of doses required), and the market requirements and manufacturing scale all affect the cost of products to create mAbs. The cost of manufacture nowadays is pegged at $US 95 and $200 per gram.

LMICs are unlikely to be able to buy monoclonal antibody products if many grams are needed. This makes the business case for antimicrobial resistance mAbs challenging, especially in light of the existence or ongoing research of alternative therapies such as vaccinations or chemically synthesized biomolecular medicines. Consequently, efforts are being made to find other methods to cut costs, such as using different cell lines, new production techniques, and infrastructures.

To further encourage the creation of innovative business/procurement strategies and inducements, such as extensive market obligations, collective sourcing, and layered pricing, clarification of mAb applications, possible demand estimates, and comprehensive value evaluations will be helpful.

Antibody Quality Testing

Check each employed antibody's specificity, selectivity, and repeatability. The next step for researchers is to evaluate the antibodies' sensitivity and specificity to see if the results can be repeated. It is crucial to run these tests inside the framework of a particular function. Antibodies, for instance, may be employed to target proteins in complicated biological or purified materials and to discern natural or degraded proteins. Specific criteria are needed for every purpose to evaluate such antibodies' effectiveness.

To serve as antigen-specific detectors, antibodies are produced and refined. Nevertheless, a method for subsequent antibody identification is necessary for their use in any specific procedure (ELISA kits and cell imaging).

In Conclusion

Custom antibody manufacturing will continue to be difficult, although one could improve the likelihood of succeeding by implementing a proactive plan to prevent typical mistakes. Reading about other real-world success stories, you may learn more about what your antibody goods should resemble. One must start with an unbiased perspective and consider whether polyclonal or monoclonal antibodies are the most fantastic suit for a particular purpose, depending on the antibody's intended use.

Thorough research, consultation, and continuous practice can help you improve your skills and experience, which will help you avoid mistakes in the antibody production process. In addition, with technological advancements, you can use simple and modified methods in production and purification, which will help you significantly reduce mistakes.