Importance and Advantages of Custom Antibody Production

Feb 9th 2023

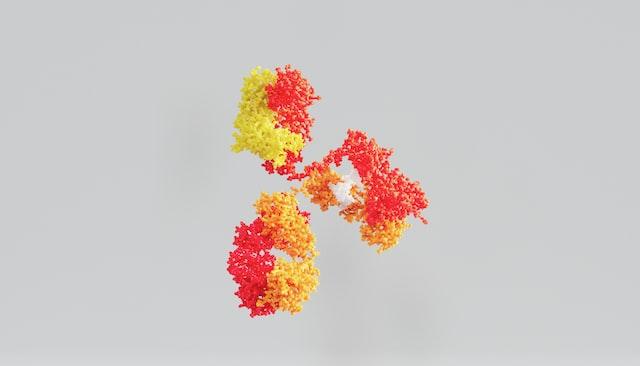

Antibodies are innate products of the body’s adaptive immune system, produced in response to disease-causing pathogens called antigens. Their primary function is to attach to the antigens via a lock-and-key mechanism, pacifying the latter. However, while endogenous antigens are literal lifesavers, their specificity limits their applications outside the body.

Thankfully, advances in biotechnology and recombinant protein production led to the development of custom antibody techniques. Custom antibody production services facilitate antibody creation for projects whereby commercially available antibodies will not do. Below is an overview of custom antibody production, including the production, steps, applications, and advantages of using custom antibody services.

Brief History of Antibodies

According to one historical account, the first mention of antibodies was in the 1890s in a publication by two pioneer immunologists. The two co-published a paper showing that the transfer of blood serum from livestock immunized against diphtheria to livestock infected with the disease cured the latter.

The scientific community was already aware of elements in the body that prevent disease, thanks to the inoculation (vaccination) campaign against smallpox in the 1770s. However, the ground-breaking publication above not only identified antibodies as the agents behind successful inoculation but revealed their potential as curative agents. Therefore, besides preventing disease, epidemiologists and other researchers could use antibodies to cure illnesses.

Other significant developments in antibody development include discovering the antibody structure and the discovery of B-cells as the specific lymphocytes that produce antibodies. Also, two researchers developed the clonal selection theory, highlighting how the B-cells produce an antibody before releasing it to fight an antigen, disputing the then-popular notion that the antigen functions as an antibody creation template.

However, the groundbreaking development in the history of antibodies was the development of the first custom monoclonal antibody in 1975. Fast forward to 2023, and antibody production gradually migrates from hybridoma technology to more advanced phage display systems. Moreover, custom antibody services utilize techniques like gene synthesis and peptide synthesis, protein expression service, and antibody sequencing services to meet the demand in the ever-growing monoclonal antibody custom service market.

Below is an overview of the steps in custom antibody production for monoclonal and polyclonal antibodies, including the pros and cons of monoclonal antibodies.

Step-by-step Custom Antibody Production

As stated earlier, antibodies have multiple applications beyond traditional vaccine preparation. The recombinant antibodies available on the market are monoclonal and polyclonal.

An antibody production company typically has commercially available polyclonal and monoclonal antibodies for general standard applications. However, there are times when a unique antigen necessitates the production of unique antibodies that are not commercially available. That is where custom antibody services come in.

Below is an overview of the general custom antibody production process. However, different antibody production service providers may charge different rates for additional steps and include exceptional support and follow-up services.

1.Custom Monoclonal Antibody Production

Monoclonal antibodies (mAbs) are the most popular in most research applications. As earlier stated, antibodies utilize a lock-and-key mechanism to bind to complementary target antigens.

mAbs' distinguishing factor is that they come from identical B-cells during de novo production. Therefore, they are exclusively compatible with one complementary antibody. They feature one binding site called an antigen determinant or epitope whereby the binding site (paratope) of a corresponding antigen attaches. Therefore, mAbs’ primary advantage is enhanced specificity.

Given the distinction between monoclonal and polyclonal antibodies, their production processes differ slightly, as highlighted below.

Peptide Design

Antibodies and antigens are natural proteins, and proteins typically feature amino acids and peptides as their building blocks. Therefore, the first step in peptide synthesis is to generate a peptide that matches the target antigen’s characteristics via antibody sequencing utilized by peptide synthesis service providers. However, the peptides have unique features, so the amino acid sequence must meet the desired characteristics.

Antigen Synthesis/ Purification

The next step after peptide design is generating the target antigen from the created peptides. Essentially, custom peptide synthesis companies are one-stop shops offering end-to-end services, including custom protein synthesis under the protein expression service. Therefore, generating the target/custom antigen is straightforward.

However, there are certain cases whereby the entity seeking custom antibody production services has the target antibody at hand. In the case of an existing antigen, the peptide design and antigen synthesis steps are unnecessary. The first step in such a case is antigen purification; an antigen must be at least 90% pure to function effectively in monoclonal antibody production.

Conjugation With a Carrier

Essentially, the antigen produced during custom monoclonal production antigen synthesis is a hapten. Immunologists define haptens as molecules that are too small to trigger an immunogenetic effect.

Therefore, immunologists attach the hapten to a larger protein molecule derived via a recombinant protein production service to add volume to the hapten, unlocking its immunogenetic effects. However, the conjugation step is also unnecessary if the synthesized antigen is large enough to trigger an immune response.

Inoculation/Vaccination

Inoculation or immunization entails injecting the purified or conjugated antigen into the spleen cells or host animal. Although multiple mammalian animal hosts can produce monoclonal antibodies, one study shows that mice are popular for mAbs production because they produce the most similar antibodies to the human immune system.

Second, mice readily produce the myeloma cells that fuse with the target B-cells to generate the hybridoma necessary for monoclonal antibody production. Hybridoma technology is the primary method used to generate mAbs.

Cell Fusion

Cell fusion entails fusing the B-cells from the animal host with the myeloma cells to form a hybridoma culture hybrid. A hybridoma is an immortal cell line that outlives standard cells and constantly reproduces.

Hybridoma Selection

Hybridoma selection entails separating the B-cells that fused with the myeloma cells from those that did not fuse. The process is crucial to monoclonal antibody production quality and quantity. It entails incubating the cell mixture derived from the host cells’ spleen in a selection medium, typically hypoxanthine-aminopterin-thymidine (HAT), for up to 14 days.

Screening of the Retrieved Cells

Antibody screening is necessary to identify and confirm that the target antibody is in the cell mixture. The hybridoma may produce other antibodies rather than the target antibody.

Cloning and Propagation

Cloning entails selecting a single line of hybridoma cells that produces the target antibodies. It ensures that the custom antibody service provider retrieves homogeneous antibodies, facilitating consistent antibody production quality in different mAbs batches produced from the same cell line.

On the other hand, propagation entails generating multiple target monoclonal antibodies from the cloned hybridoma cell line. The alternative to cloning and propagation is a significantly lengthier process that entails sorting out the cell lines one by one. Also, the cloned cell lines receive a clone number that facilitates mAbs tracking back to this parent cell line.

Characterization and Storage

Monoclonal antibody characterization utilizes peptide mapping to establish peptide sequence, primary structure, and the antibody’s mass. The process uses mass spectrometry techniques to confirm the expected target antibody sequence and antibody homogeneity.

After characterization, the antibody services store the target monoclonal antibodies in ideal conditions for shipment to the customer that made the order. Monoclonal antibody production using hybridoma technology can take up to several months, depending on the antibody’s complexity and whether the process commences from peptide design or antigen purification.

2.Monoclonal Antibody Production Using Phage Display

Besides the hybridoma technology described above, immunologists can utilize another protein production service based on phage display to generate custom monoclonal antibodies. The phage display technique entails separating the genes in an antibody by weight and introducing them into a bacteriophage protein.

Consequently, the different bacteriophage proteins bearing the antibody genes show the specific genes on their surface. After creating the bacteriophage displays, the antibody production companies add the displayed gene to a gene library.

They then screen the library against the antigens of interest to identify the gene sequences that correspond with the target antigen. After identifying the target genes, the final step is characterizing and storing the target antibody.

3.Custom Polyclonal Antibody Production

Unlike monoclonal antibodies generated from a singular B-cell line, polyclonal antibodies arise from different B-cell lines. Therefore, they target a single corresponding antigen, and they feature different epitopes. Polyclonal antibodies share some production steps with monoclonal antibodies but have specific unique steps, as highlighted below.

Peptide Design and Antigen Synthesis

The first two steps in custom polyclonal antibody production (Peptide design and Antigen synthesis) are identical to the first three in monoclonal antibody production. Therefore, refer to the segment above for details on how each step works.

Inoculation

Unlike custom monoclonal antibodies, custom polyclonal antibody production is effective in more animal hosts than mice. However, rabbits are the preferred custom polyclonal antibody host because they are larger, facilitating higher serum collection per host with minimum injections.

Second, the rabbits are easier to inject, facilitating more humane serum collection practices. However, chickens emerge as favorable polyclonal antibody hosts because the antibodies form in the eggs, facilitating non-invasive antibody retrieval.

Serum Catching

Serum catching entails retrieving the antiserum from the host animal after exposure to the antigen. However, how long it takes to recover the serum depends on how long it takes specific animal hosts to produce antibodies.

Titer Analysis

A titer analysis is a test to determine how much of the target custom polyclonal antibody is present in the harvested antiserum. Researchers can use enzyme-linked immunosorbent assays (ELISA kits) to administer the titer tests.

Antibody Purification

Antibody purification entails separating the target custom polyclonal antibody from a crude organic mixture. The antibody production company utilizes different techniques, including chromatography and mass spectrometry, depending on the target antibody’s characteristics to avoid denaturing the protein.

Antibody Characterization

Custom polyclonal antibody characterization entails examining the purified antibody to establish its physical and chemical characteristics. It is a form of quality analysis and quality control to ensure that only the best-quality custom antibodies make it to the order fulfillment batch.

Importance of Custom Antibody Production

Custom antibodies have numerous applications within and outside the biotech industry, as highlighted below.

1.Therapeutics

Non-commercially available monoclonal and polyclonal antibodies significantly treat and manage various illnesses, including cancers and highly infectious diseases. Researchers use their antigen-binding activities to carry drugs to targeted areas. According to one industry report, the FDA has approved 30 monoclonal medications for use, while more await approval in the clinical research stage.

2.Diagnostics and Clinical Projects

Custom polyclonal antibodies and their affinity for multiple antigens play a significant role in antigen detection devices like ELISA kits. Researchers and biochemists use polyclonal antibodies for the biochemical analysis of biological samples. Second, they function as biorecognition elements coupled with labeling agents to facilitate diagnostic imagery.

3.Basic, Clinical, and Translational Research Applications

Recombinant custom antibodies play a significant role in research, facilitating concept development, actualization, and implementation. First, they are integral to basic research, which helps improve understanding of antibody behavior and how other body systems work.

Second, they are pivotal to clinical research, helping to explore the effectiveness of the various antibody therapeutics and vaccines employed in disease management. Third, custom antibodies are also helpful in translational research, helping to apply the findings from clinical research to real-life situations.

Advantages of Custom Antibody Production

Both antibody types highlighted above have numerous benefits to research and other industry-specific applications. Below is an overview of each such benefit.

- Custom monoclonal antibodies provide unparalleled homogeneity thanks to the cloning stage included in the process. Therefore, researchers using antibodies can avoid fluctuating results that derail or compromise the entire project. Moreover, clone number assignment allows the researcher to order a different batch of homogenous custom monoclonal antibodies for future projects.

- Fewer antigens are necessary to induce the antibody production process in custom monoclonal and polyclonal antibody production. Moreover, the custom peptide design and recombinant antigen production eliminate the need for antigen characterization.

- Scaling up custom monoclonal antibody production is easy thanks to the molecules’ enhanced stability facilitated by upstream modifications.

- Custom polyclonal antibodies are cheaper and take a significantly shorter period, thanks to fewer production steps.

- Custom polyclonal antibody production steps utilize different hosts to suit project needs.

Conclusion

Custom antibody production plays a crucial role in medical advancement, developing novel monoclonal and polyclonal antibodies. However, consult your custom antibody service provider to ensure that the antibody type and production methods you choose are ideal for your project. Most custom antibody production companies offer free consultations.