A Basic Introduction To Peptide Synthesis

Sep 30th 2022

A Basic Introduction To Peptide Synthesis

The biological and chemical process of life consists of various crucial factors. There are building blocks or compounds that, as their name suggests, formulate the backbone of life on a cellular level, and when they combine with other elements, they play a crucial functionary role.

With the advancement of molecular research and biochemistry, it has become possible to develop or conjoin compounds in a lab and use them for various purposes in medicine, industry, pharmaceuticals, etc. Various cutting-edge processes, like custom gene synthesis, custom protein production, recombinant protein production, etc., have gained popularity in science and research.

Determination of Amino Acids

Amino acids are the molecules that enable the formation of proteins. Amino acids and proteins are considered the building blocks of life. In the human body, amino acids play significant roles, such as repairment of body tissues, breaking down food, growth, and other bodily functions. Additionally, they also act as a source of energy for the body.

Protein can be further expressed using protein purification techniques and E.coli protein aggression and is extensively used by ELISA Kit manufacturers for sampling and testing purposes. Protein Expression and Purification services are also provided for commercial purposes in assisting big pharmaceutical firms.

Amino acids and proteins are used for antibody production services, such as identifying the proper antibody production steps, antibody sensitivity, and how to do ELISA tests

Before understanding the peptide synthesis process, you need to know about the biological nature of amino acids, particularly those most suited for peptide synthesis. Investigators that provide peptide synthesis services or Protein expression and purification services notably use these amino acids for the best results.

Proteinogenic Amino Acid is one such substance. They are known for acting as the material base of proteins. They are inserted biosynthetically during the synthesis or expression procedure. As the name suggests, proteinogenic means “protein creating.” The type of acids usually is L-amino acids, except glycine.

Amino acids are further divided into essential amino acids, non-essential amino acids, and conditional amino acids. Some of the essential amino acids are:

- Histidine

- Isoleucine

- Leucine

- Lysine

- Methionine

- Phenylalanine

- Threonine

- Tryptophan

- Valine

Non-essential amino acids aren’t derived from food sources as essential ones. They include:

- Alanine

- Arginine

- Asparagine

- Aspartic acid

- Cysteine

- Glutamic acid

- Glutamine

- Glycine

- Proline

- Serine

- Tyrosine

What are Peptides?

Peptides are strings of amino acids that are present in the human body. These amino acids function as protein developers; however, a peptide doesn’t contain the same number of proteins as amino acids. Peptides can also be generated in labs, and they are just the same as found in your body.

Various gene synthesis companies and commercial peptide synthesis companies, alongside providing services such as protein expression and purification services , recombinant protein expression, and Monoclonal antibody sequencing, Peptide Synthesisis also hugely employed for their usage in a medicinal capacity.

Additionally, these commercial agents, alongside providing peptide synthesis services, also research antibody sensitivity,e-coli protein aggression, andElisa kits.

Peptides are used extensively to study and enhance the pharmaceutical treatment of diseases such as diabetes and sclerosis. Additional studies have also found that certain kinds of peptides play a beneficial role in your skin, muscles, and body weight. There are various kinds of peptides, such as:

- Dipeptides

- Tripeptides

- Oligopeptides

- Polypeptides

How are Peptides produced?

As mentioned above, peptides are made by formulating a chain of amino acids. During the production process, the carboxylic acid of one amino acid conjoins with the amine group of another acid. The uniqueness of every amino acid is generally devised for their respective functional group, which is traditionally called the R group.

This functional R group usually determines a peptide's overall shape, structure, and property. To understand the intricacies of peptide production, we need first to understand the role of amino acids, mainly when they are used to synthesize peptides.

During the synthesizing process, there should be adequate protection for the amine group of amino acids to avoid any unwarranted reactions. A molecule known as the FMOC is used to achieve this result.

However, before the attachment between the two amino acids is completed, the FMOC from the side of the amine group must be removed. You can keep the FMOC on one side of the amino acid; otherwise, it will start coupling with itself.

The two traditional methods of peptide production are:

- Liquid phase peptide synthesis:

- Solid phase peptide synthesis (SPPS)

Solid Phase Peptide Synthesis

Developed by Nobel Prize-winning chemist Robert Bruce Merrifield in 1963, the Solid Phase Peptide Synthesis (SPPS) has become the most traditional method of Peptide Synthesis. The fundamental aspect of SPPS is the attachment of every Peptide chain with polystyrene beads.

This process has enabled the possibility of exploring a peptide inside a vessel. The vessel utilizes a filter to retain peptide-connected resin, retrospectively allowing the drainage of solutions.

The process is initiated with an amino acid already attached to a resin. Furthermore, the steps that follow usually go something like this:

- Removal of FMOC from amine side group of amino acids

- Addition of subsequent amino acids in the strain

- Activation of coupling reagents

- Repetition of the first three steps until completion of the sequence

- Cleaving the peptide from the resin

It’s worth remembering that an individual FMOC group protects the amine side of every amino acid. As mentioned above, the attachment of two amino acids is done by coupling the NH2 side of single amino acid with the COOH side of another.

As a result, The FMOC group is removed. When another amino acid is added to the process, there is a natural bonding g between both sides of the deprotected amino acid.

Various aspects of SPPS

1.FMOC

The FMOC SPPS is one of the ideal methods of Peptide synthesis. The is widespread availability of enhanced quality FMOC manufacturing blocks at low prices. Additionally, some FMOC blocks come with modifications that supplement the production of peptides depending on the nature of production.

The growing interest in the commercial development of peptides has also, in exchange, increased the requirement of FMOC applications and aided their technological advancements.

Due to its significant role in the synthesis process, FMOC amino acids have to be highly pure; otherwise, there’s a high possibility of coupling failure. Impurities in the FMOC compound can be assessed using the HPLC analysis, which is usually the preferred quality testing method.

Additionally, when adding FMOC amino acid to your solution, ensuring that the substance isn’t plagiarised or adulterated is extremely important. This may result in many copied FMOC compounds in the same peptide strain.

Naturally, with many reactions coinciding, the chances of side reactions are high. Several side chain protection methods are used to cope with these problems that branch out to formulate other unnecessary compounds and compromise the chemical process. Some of the chemicals used to enable the process are:

- Aspartic Acid

- Arginine

- Cysteine

- Histidine

Lastly, the success of the synthesis procedure depends on the FMOS SPPS efficiency, and peptide insolubility is one of the greatest hindrances. To aid solubility, the composition of your amino acid solution plays a crucial role. Hence, the peptide's dissolution and amino acid sequence should be adequately studied. There are many schemes used to increase the solubility, and different agents and methods are used, such as:

- Phosphorylation

- Sulfation

- Farnesylation

- Methylation

- Citrullination

- Glycosylation

The Potential for FMOC SPPS is enormous. However, if not carefully curated or the compounds involved in the process aren’t appropriately expressed, it may impact the synthesis process. But with constant improvement through research and practice, the future of FMOC in peptide synthesis is bright.

2. Deprotection and Resin Cleavage

After the synthesis process has been completed using the FMOC SPPS method, the crucial task is to remove all the side chain protecting elements used during the peptide synthesis procedure, particularly the detachment of the peptide from the supported resin.

If this task is left incomplete, there’s a high chance of damage to the newly synthesized peptide and the bondage of amino acids with other amine group compounds. This process is also known as deprotection. The FMOC SPPS system is usually done by tending to the peptidyl resin with TFA.

For this purpose, highly reactive cationic species of protected groups are created and modified using the functional groups Trp, Met, Tyr, and Cys. Numerous cleavage mixtures are available; however, the most used and famous is the Reagent K.

The following code necessitates that the N-terminal FMOC be removed using the chemical piperidine before cleaving the resin from the respective peptide. Afterward, the resin must be cleaned thoroughly using the non-reactive DMF synthesis substance. You can also use acidic agents to aid the release of the peptide. Remember to properly wash and dry the resin before cleaving.

Since the conditions for cleavage depends on the nature of the amino acids and their composition. Each cleavage comes with its own set of challenges. However, with a proper understanding of the resin behavior, you can complete the cleaving process regardless of the size of the whole process.

There are various methods used for deprotection and resin cleavage. Some of them are:

- General TFA cleavage

- TMSBr cleavage

- Diluted TFA cleavage

- TFE/DCM cleavage

- Borohydride cleavage

- Oxidative cleavage

All these methodssuccessfully separate the protective FMOC for the generated peptide while maintaining their solubility. You have seen that deprotection is a complicated process with lots of materials and chemicals, so you must select the best and most effective option available.

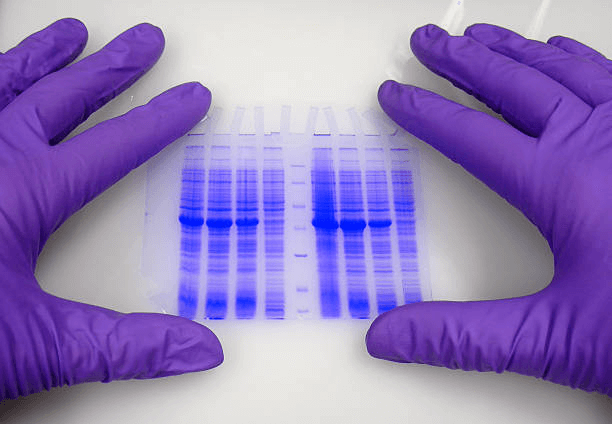

3. Peptide Purification

One of the most cumbersome activities in peptide synthesis can be removing unwanted components or residual effects from the amino acid coupling. What makes purification difficult is identifying the unnecessary substance primarily because they look so similar to the desired products. Some of the common impurities that can be found during or after the procedure are:

- Deletion peptides

- Truncated peptides

- Scavengers

- By-products of protection elements

Since the impure materials are distinctly similar to the outcome, the identification process must be very particular. UV peak detention and reversed-phase high-performance liquid chromatography can be used to seek impure materials.

However, during this procedure, ensure that the inherent qualities of the synthesized peptide are preserved, and only the impurities are removed.

To accomplish this smoothly, the stability of the chemicals concerning, particularly, their acidic, basic and neural eluted solvents. Additionally, since the natural properties of a peptide depend upon the sequential and compositive nature of the amino acids they are bonded with, their impurities also show similar characteristics; hence it’s important to separate them diligently.

As mentioned earlier, UV detection is a determinant method for maintaining peptide purity. After the UV purification process, the end product is generally delivered in TFA salt form. The HPLC formula can also be enhanced by choosing an optimal buffer system, stationary phase, gradient, and column temperature.

Others aspects that should be kept in mind during the purification process are the Net Peptide Content which is related to the number of materials in the peptide that are unnecessary for the substance. You can also conduct an amino acid analysis to determine the NPC in your expression.

Finally, it’s important to remember that the purity of a peptide differentiates with every batch, and ideally, 90% purity is considered the gold standard for successful peptide synthesis.

Liquid phase peptide synthesis

Before the discovery of SPPS, the preferred peptide synthesis method was the liquid phase. Earlier it was called the standard organic chemistry solution. The American biochemist Vincent du Vigneaud also won the Nobel prize in chemistry after he determined that peptides could be synthesized using the LPPS method.

However, the feasibility of peptide synthesis using the SPPS method is much more potent. The classical nature of peptide synthesis is still used for large-scale production of peptides, particularly for industrial purposes.

Conclusion

Custom Peptide Synthesis is a crucial biological procedure to understand the intricacies of molecular substances and their traditional roles in your body, like growth, healing, and energy source.

With SPPS, the process of synthesis has become more accessible and much more effective, particularly when it comes to peptide purity. Peptide synthesis companies are rapidly using these services for further research into the discipline so that new advancements can be made.